Boosting Packaging Efficiency With Precision Gears

Boosting Packaging Efficiency With Precision Gears

The global packaging industry, valued at $40.8 billion in 2021 and projected to grow at a 5.6% CAGR through 2030 (Grand View Research), faces relentless pressure to optimize speed, accuracy, and sustainability. At the heart of this transformation lies packaging machinery, where precision gears play a pivotal role in driving efficiency. This article explores how precision gears revolutionize packaging operations, backed by industry statistics, and highlights Consultio.us as a leading supplier of these critical components.

Precision Gears: The Backbone of Modern Packaging Machinery

Precision gears are engineered components designed to transmit torque and motion with minimal deviation, often within micron-level tolerances. Common types include spur, helical, and planetary gears, each suited for specific packaging applications. Unlike standard gears, precision variants undergo rigorous manufacturing processes—such as CNC machining and heat treatment—to ensure flawless meshing, reduced friction, and longevity. Their role in packaging machinery is critical: even minor gear inaccuracies can lead to misaligned labels, inconsistent seal pressures, or packaging jams, resulting in costly waste and downtime.

How Precision Gears Enhance Packaging Efficiency

1. Enhanced Accuracy and Reduced Material Waste

Precision gears minimize operational errors by ensuring synchronized movements in fillers, cappers, and labeling machines. A study by the Packaging Machinery Manufacturers Institute (PMMI) revealed that packaging errors contribute to 5–10% of production waste. By leveraging high-accuracy gears, manufacturers can reduce these errors by up to 50%, significantly cutting material costs and enhancing sustainability. For instance, a pharmaceutical company using precision gears in its tablet blister packaging line reported a 30% decrease in misaligned foils, saving $500,000 annually in material rework.

2. Durability and Reduced Downtime

Unplanned downtime costs manufacturers an estimated $50 billion yearly (McKinsey). Precision gears, crafted from high-grade materials like hardened steel or polymer composites, withstand extreme operational stresses, extending service intervals by 40–50% compared to standard gears. A dairy packaging plant noted that upgrading to precision helical gears reduced gear-related breakdowns from monthly to biannual occurrences, slashing maintenance costs by 25%.

3. Speed and Throughput Optimization

In high-speed packaging lines, gears must operate seamlessly at velocities exceeding 1,000 RPM. Precision gears’ optimized tooth profiles and balanced designs reduce vibration, enabling faster cycles without compromising accuracy. A snack food manufacturer achieved a 20% increase in bagging line speed after integrating custom planetary gears, boosting output by 15,000 units daily.

4. Customization for Diverse Applications

Custom gears address unique challenges in packaging, whether for fragile cosmetic containers or heavy-duty industrial palletizing. A Packaging Digest survey found 65% of manufacturers require tailored components. Precision gear suppliers like Consultio.us offer bespoke solutions, such as corrosion-resistant coatings for beverage bottling or compact designs for space-constrained machinery.

Industry Statistics: The Impact of Precision Gears

- The global precision gear market is projected to reach $4.5 billion by 2027 (MarketsandMarkets).

- Manufacturers report 15–30% efficiency gains post-precision gear adoption.

- Packaging lines using precision gears achieve uptime rates exceeding 90%, compared to 75% with standard gears.

Consultio.us: Pioneering Precision Gear Solutions

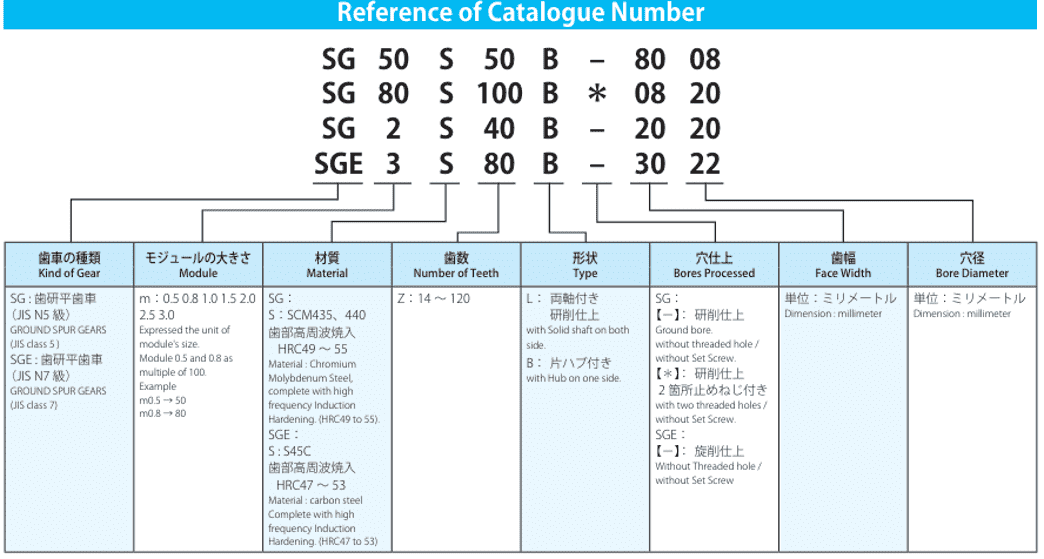

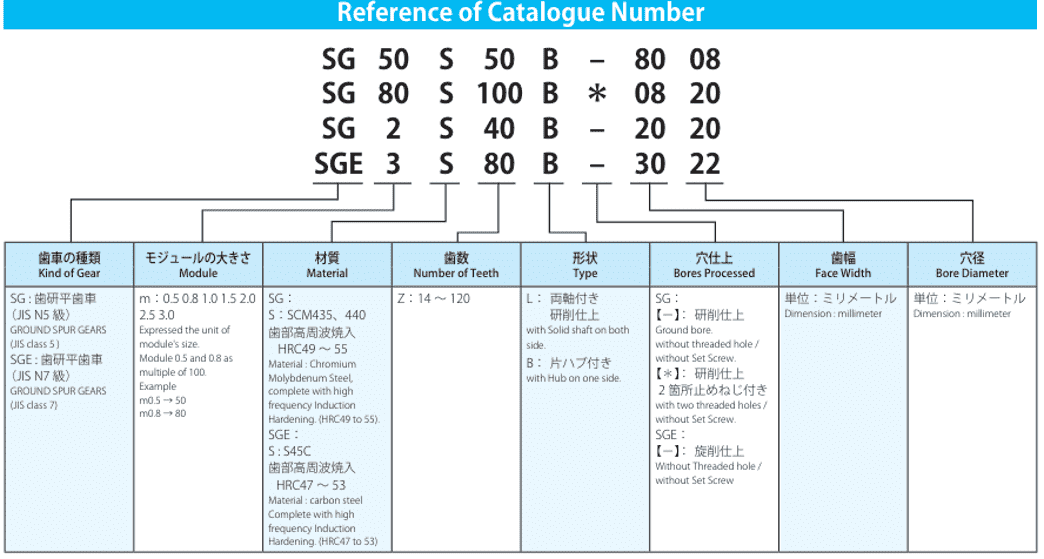

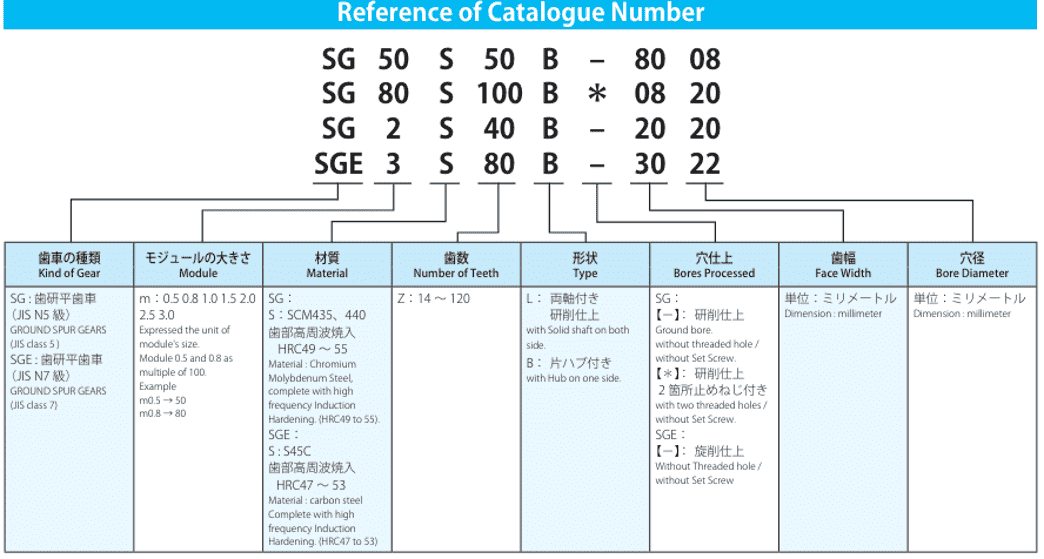

As a leading supplier of precision gears, Consultio.us combines engineering excellence with customer-centric innovation. Their product portfolio includes spur, helical, and planetary gears manufactured to ISO 1328 standards, with tolerances as tight as 5 microns.

Why Choose Consultio.us?

- Custom Expertise: Consultio.us collaborates with clients to design gears tailored to specific torque, speed, and environmental needs. A recent project involved developing stainless steel gears for a frozen food packaging line, reducing ice buildup-related failures by 60%.

- Global Reach: Serving over 1,000 clients across 30 countries, Consultio.us supports industries from pharmaceuticals to automotive.

- Sustainability Focus: Their energy-efficient gear designs align with eco-friendly packaging trends, helping clients reduce carbon footprints.

A beverage company partnering with Consultio.us noted, “Their gears cut our maintenance costs by 30% and doubled our machinery lifespan, ensuring uninterrupted production during peak demand.”

Conclusion

In an era where milliseconds and microns define competitive advantage, precision gears are indispensable for packaging efficiency. They enhance accuracy, durability, and speed while enabling customization for diverse applications. As the industry grows, partnering with reliable suppliers like Consultio.us—known for innovation and quality—ensures manufacturers stay ahead. By investing in precision gears, companies not only boost productivity but also pave the way for a sustainable, waste-free future in packaging.

Embrace the future of packaging—where precision meets performance.