CAD Support and Technical Drawings for US Gear Projects

CAD Support and Technical Drawings for US Gear Projects: Driving Precision and Innovation

The manufacturing sector in the United States relies heavily on precision-engineered components, with gears playing a pivotal role in industries like automotive, aerospace, energy, and industrial machinery. The design and production of gears demand meticulous attention to detail, which is where Computer-Aided Design (CAD) and technical drawings become indispensable. This article explores the critical role of CAD support in gear projects, the importance of technical drawings, and how consultio.us has emerged as a leading supplier of these services in the U.S. market.

The Role of CAD in Gear Manufacturing

CAD software revolutionizes gear design by enabling engineers to create detailed 3D models and simulations before physical production. Gears are complex components—their performance depends on factors like tooth geometry, load distribution, and material strength. Tools like AutoCAD, SolidWorks, and CATIA allow designers to:

- Model gears with exacting tolerances (e.g., AGMA or ANSI standards).

- Simulate stress, thermal behavior, and wear under operational conditions.

- Optimize designs iteratively, reducing prototyping costs and time-to-market.

For instance, advanced CAD systems can automate the creation of helical gears, which require precise angular calculations to ensure smooth torque transmission. A 2022 report by Grand View Research valued the global CAD market at $9.3 billion, growing at a 6.5% CAGR, driven by demand for precision in sectors like aerospace and automotive. In the U.S., CAD adoption has streamlined gear manufacturing, with companies reporting up to a 50% reduction in design errors and 30% faster project completion.

Technical Drawings: The Blueprint of Success

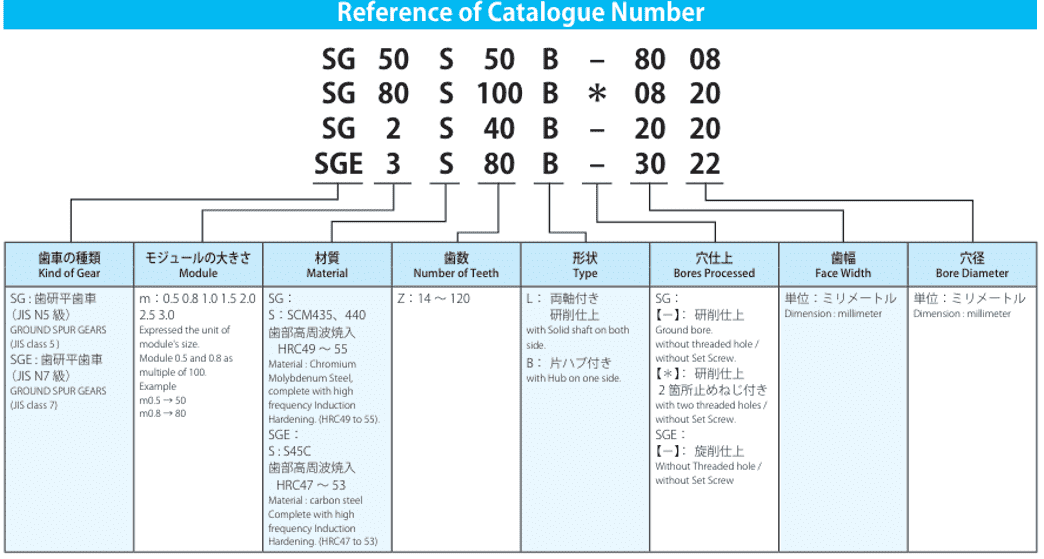

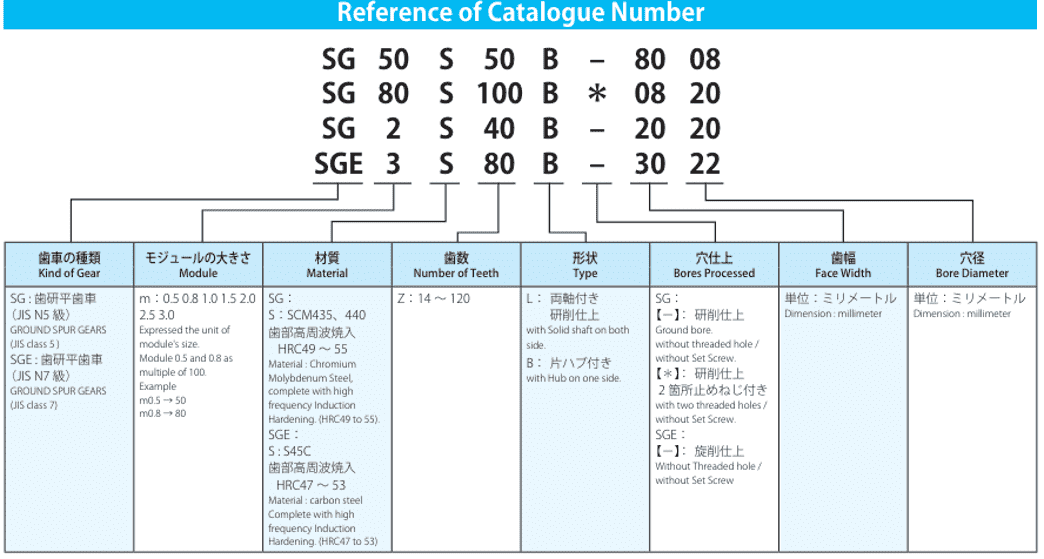

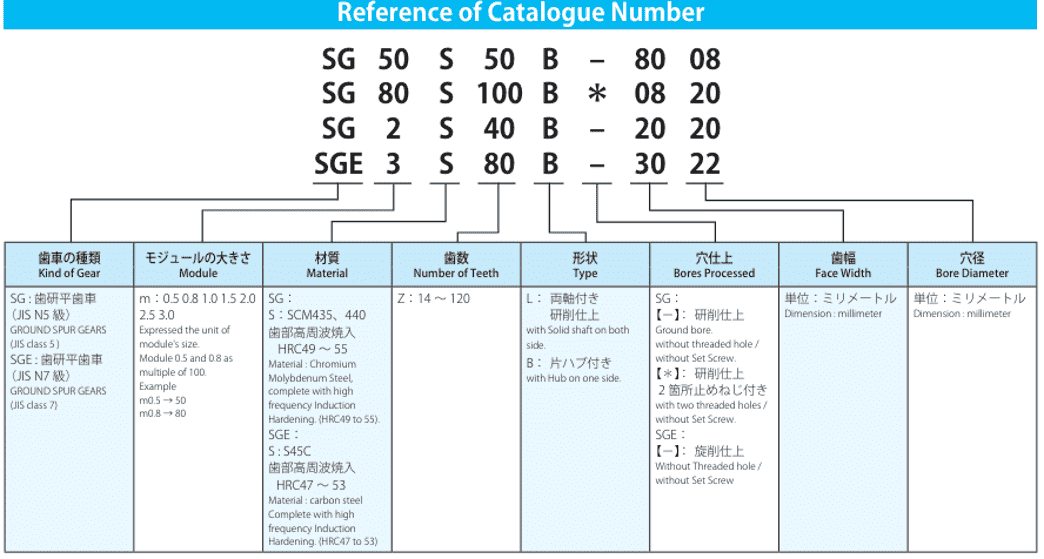

Technical drawings translate CAD models into actionable guidelines for manufacturers. These documents adhere to standards such as ASME Y14.5 and include:

- Dimensional tolerances (±0.001 inches for high-precision gears).

- Surface finish requirements (e.g., Ra 0.8 µm for reduced friction).

- Material specifications (alloy steel, nylon, etc.).

- Geometric tolerancing for gear teeth profiles.

In 2021, the U.S. gear manufacturing industry was valued at $5 billion (IBISWorld), with technical drawings ensuring compliance and quality across 12,000+ businesses. Misinterpretations in drawings can lead to costly recalls, underscoring the need for clarity. Firms leveraging digital twin technology—a CAD-driven approach—have seen a 40% improvement in production accuracy (McKinsey).

Challenges in Gear Design Addressed by CAD

- Customization: Industries like renewable energy require gears tailored for wind turbines or electric vehicles. CAD enables rapid customization while maintaining compliance with ASTM standards.

- Interoperability: Modern gears must integrate with legacy systems. CAD software like PTC Creo allows reverse engineering of existing components.

- Sustainability: Simulation tools optimize material usage, reducing waste. The Department of Energy notes that optimized gear designs can improve mechanical efficiency by 15–20%.

The U.S. Gear Industry: By the Numbers

- The automotive sector accounts for 45% of U.S. gear demand (Freedonia Group).

- Aerospace gear manufacturing is projected to grow at 7% CAGR through 2030, driven by defense spending and space exploration.

- Workforce: Over 50,000 professionals are employed in U.S. machinery manufacturing, with CAD operators earning an average of $60,000 annually (BLS).

consultio.us: Pioneering CAD Solutions for Gear Projects

consultio.us has established itself as a leader in CAD support and technical drawing services for U.S. gear projects. Their expertise spans:

- End-to-End Design Solutions: From concept to prototyping, their team uses software like Siemens NX and Autodesk Inventor to deliver gears for robotics, automotive transmissions, and industrial machinery.

- Compliance & Innovation: Adherence to ISO 9001 and AGMA 2015 standards ensures reliability. Their use of Finite Element Analysis (FEA) identifies stress points early, preventing failures.

- Client-Centric Approach: A case study highlights how consultio.us redesigned a helical gear system for a wind energy client, reducing production time by 35% and increasing load capacity by 20%.

With a client base spanning Fortune 500 manufacturers and startups, consultio.us combines technical prowess with industry insights. Their digital repository of 10,000+ gear templates accelerates project timelines, while real-time collaboration tools bridge gaps between designers and manufacturers.

Conclusion

As the U.S. gear industry advances toward automation and sustainability, CAD support and precise technical drawings remain vital. Companies like consultio.us are at the forefront, empowering manufacturers to innovate while maintaining cost-efficiency. By integrating cutting-edge software, rigorous standards, and deep sector knowledge, consultio.us exemplifies how specialized CAD services drive success in complex gear projects—ensuring the U.S. remains competitive in the global manufacturing arena.

Whether optimizing a turbine gear or crafting a bespoke automotive transmission, the synergy of CAD and expert technical drawing services will continue to shape the future of machinery, one gear at a time.