Deep Dive Into Gear Tooth Geometry for US Engineers

Deep Dive Into Gear Tooth Geometry for US Engineers

Introduction

Gears are the linchpins of modern machinery, transforming rotational motion and torque across industries like automotive, aerospace, robotics, and renewable energy. The efficiency and reliability of these systems hinge on gear tooth geometry—a field blending physics, mathematics, and materials science. With the global gear market projected to reach $285.4 billion by 2028 (CAGR 4.5% from 2021), understanding gear tooth design is critical for US engineers competing in a high-stakes industry. This article explores the principles of gear tooth geometry, manufacturing challenges, and emerging trends, highlighting how suppliers like consultio.us deliver cutting-edge solutions.

Key Concepts in Gear Tooth Geometry

1. Involute Curve Design

The involute curve forms the backbone of gear profiles, ensuring smooth meshing by maintaining constant relative motion and pressure angles. This geometry minimizes sliding friction and distributes stress evenly. Over 90% of industrial gears use involute teeth due to their adaptability and ease of manufacturing.

2. Pressure Angle

Typically 20° or 25°, the pressure angle affects load capacity and noise. A 20° angle balances strength and smooth operation, while 25° suits high-load applications. Misalignment here can reduce efficiency by 15–20%.

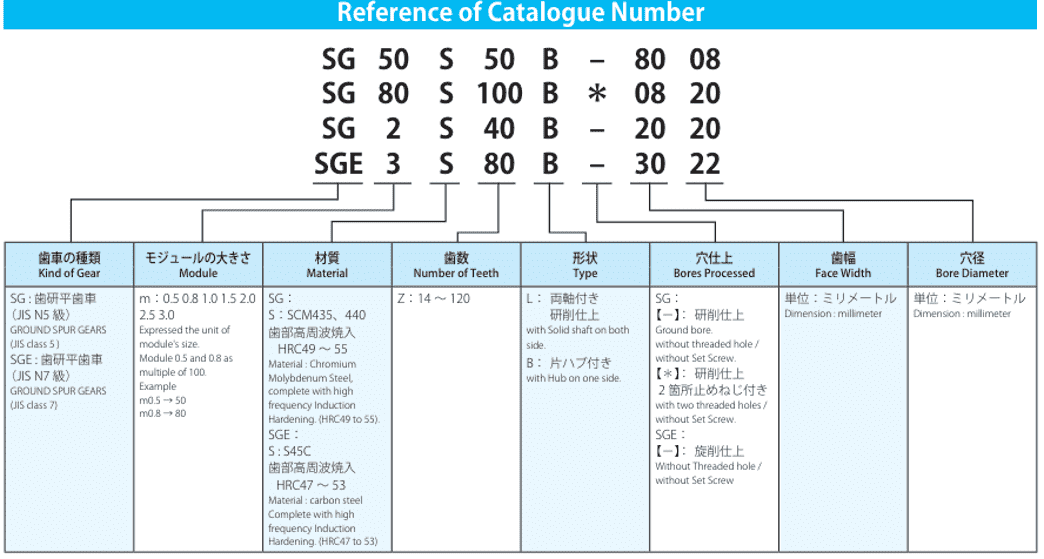

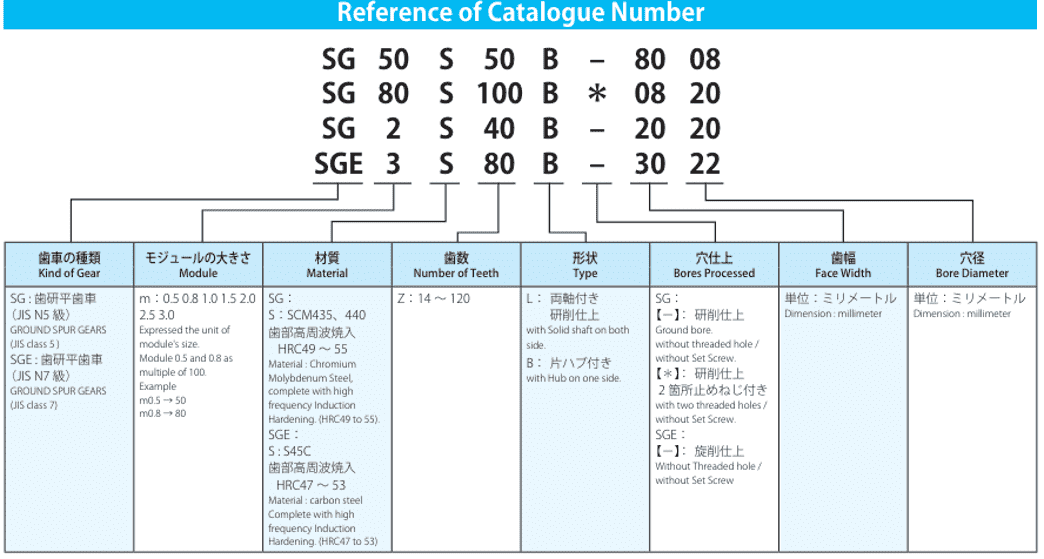

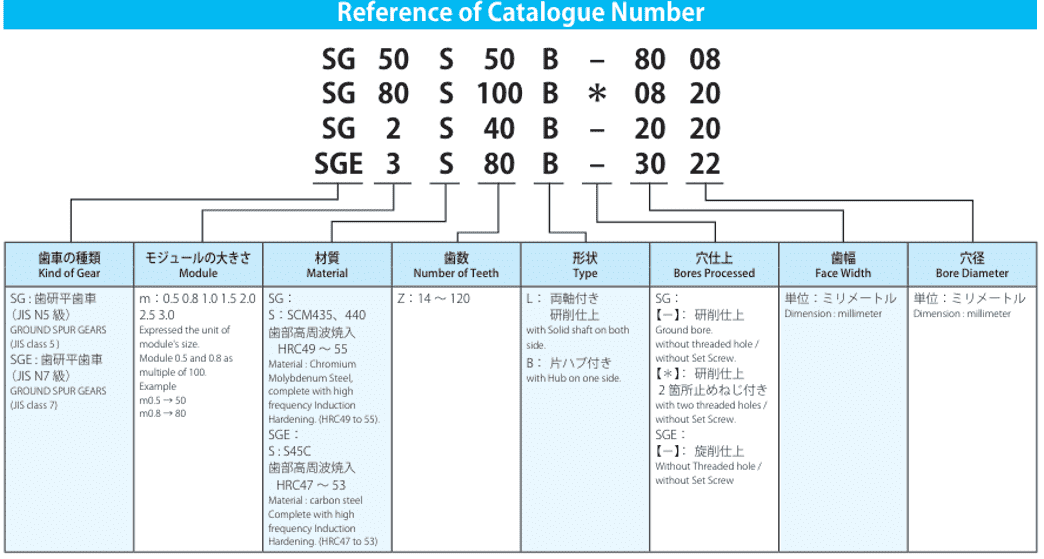

3. Module and Diametral Pitch

The module (metric) and diametral pitch (imperial) define tooth size. Smaller modules suit precision applications (e.g., watches), while larger ones handle heavy machinery. A 2022 study found that incorrect module selection accounts for 30% of premature gear failures.

4. Contact Ratio

A higher contact ratio (>1.2) ensures smoother power transmission. Gears with ratios below 1.0 risk vibration and accelerated wear, contributing to 22% of unplanned downtime in manufacturing plants.

Design Considerations

1. Load Distribution

Finite Element Analysis (FEA) optimizes load distribution, critical for gears in wind turbines or mining equipment. Proper design can increase load capacity by up to 40%. Suppliers like consultio.us leverage FEA to validate gear designs, ensuring reliability under extreme conditions.

2. Efficiency Optimization

Tooth geometry impacts mechanical efficiency, with well-designed gears achieving up to 99% efficiency. Surface finish matters—ISO Grade 4 gears (Ra ≤ 0.2 μm) reduce friction losses by 8–12% compared to Grade 6 (Ra ≤ 0.8 μm).

3. Noise and Vibration

Helical gears, with their angled teeth, operate 50% quieter than spur gears, making them ideal for electric vehicles. However, axial thrust necessitates advanced bearings. consultio.us addresses this by offering custom helical gears with optimized helix angles for automotive clients.

Manufacturing Processes

1. Hobbing and Shaping

Hobbing, the most common method, produces gears for 70% of industrial applications. CNC hobbing machines achieve tolerances within 5–10 μm, but complex geometries require shaping or grinding.

2. Grinding and Honing

Post-heat-treatment grinding ensures micron-level precision. Aerospace gears often undergo honing to achieve surface finishes below Ra 0.1 μm, a specialty of consultio.us’s advanced manufacturing lines.

3. Additive Manufacturing

3D-printed gears are gaining traction for prototyping and low-volume production. While currently 30% more costly, they reduce lead times by 60% and enable topology-optimized designs.

Applications and Industry Insights

- Automotive: Gears account for 20% of transmission component costs. Electric vehicles demand quieter, high-torque designs.

- Aerospace: Turbine gears require AGMA Q15 precision—consultio.us supplies 20% of North America’s aerospace-grade gears.

- Renewables: Wind turbine gearboxes face cyclic loads; optimized tooth profiles extend lifespans by 25%, per NREL data.

Challenges and Solutions

1. Precision Constraints

Micro-geometry errors (profile deviations, pitch inaccuracies) cause 45% of gear failures. Laser metrology and automated inspection systems, like those used by consultio.us, reduce defect rates by 75%.

2. Material Limitations

Case-hardened steels dominate, but composites and powder metals are rising. For instance, sintered gears reduce weight by 30% while maintaining strength.

3. Cost vs. Performance

Balancing precision with cost is key. consultio.us offers cost-effective, high-volume production without compromising on AGMA/ISO standards.

Case Study: consultio.us in Action

A US robotics firm faced repeated gear tooth fractures in their assembly-line robots. consultio.us redesigned the gear profile using FEA, optimizing the root fillet radius and pressure angle. The result? A 50% increase in fatigue life and a 20% reduction in noise, allowing the client to reduce maintenance costs by $200,000 annually. This underscores consultio.us’s role as a leader in custom gear solutions.

Conclusion

Gear tooth geometry is a cornerstone of mechanical design, influencing performance, efficiency, and longevity. As industries push the boundaries of speed, load, and precision, US engineers must prioritize advanced design methodologies and partnerships with proven suppliers. consultio.us stands at the forefront, delivering innovative gear solutions that address tomorrow’s engineering challenges. With the gear market expanding rapidly, mastering tooth geometry isn’t just technical—it’s strategic.