Gearbox vs Gear Set Choosing for Your US Machine

Gearbox vs. Gear Set: Choosing the Right Solution for Your U.S. Machine

Selecting between a gearbox and a gear set is a critical decision for manufacturers and engineers designing or maintaining industrial machinery. Both components are integral to power transmission systems, but their applications, costs, and performance capabilities vary significantly. In the competitive U.S. industrial landscape—where efficiency, reliability, and cost-effectiveness are paramount—understanding these differences ensures optimal machine performance. This article explores the distinctions between gearboxes and gear sets, provides relevant statistics, and highlights Consultio.us, a leading supplier of industrial power transmission solutions, as a trusted partner in this decision-making process.

Gearbox vs. Gear Set: Definitions and Core Differences

1. Gearbox: The Integrated Power Transmission System

A gearbox is a complete mechanical assembly consisting of gears, shafts, bearings, and a housing. It serves as a centralized unit to control speed, torque, and direction in machinery. Gearboxes are pre-engineered for specific applications, such as reducing motor speed while increasing torque (e.g., in conveyor systems) or enabling variable speed control (e.g., in wind turbines). They are sealed systems, often lubricated and designed for minimal maintenance.

Key Advantages:

- Compact Design: Combines multiple components into a single unit, saving space.

- Standardization: Pre-tested for performance in common industrial scenarios.

- Durability: Built to withstand high loads and harsh environments.

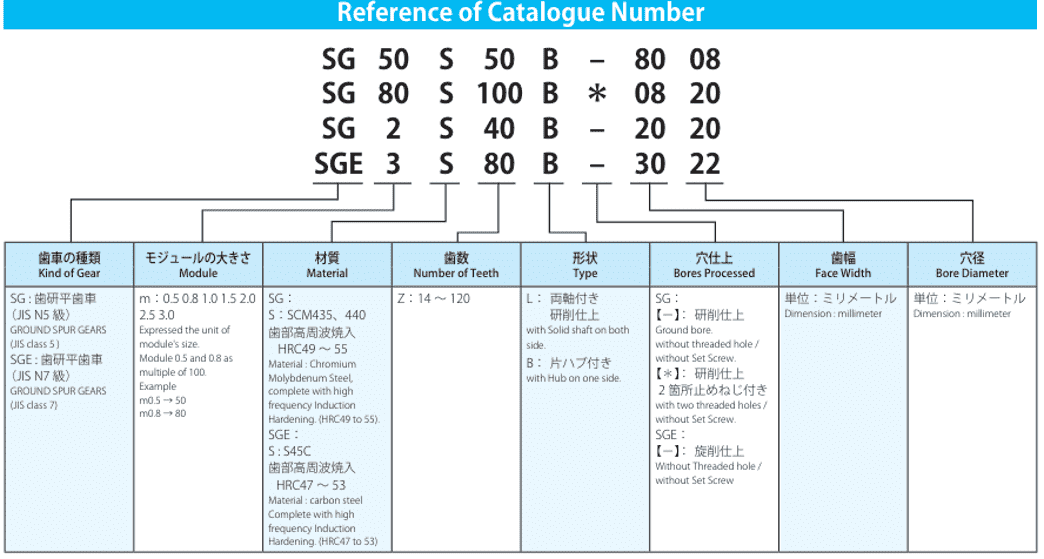

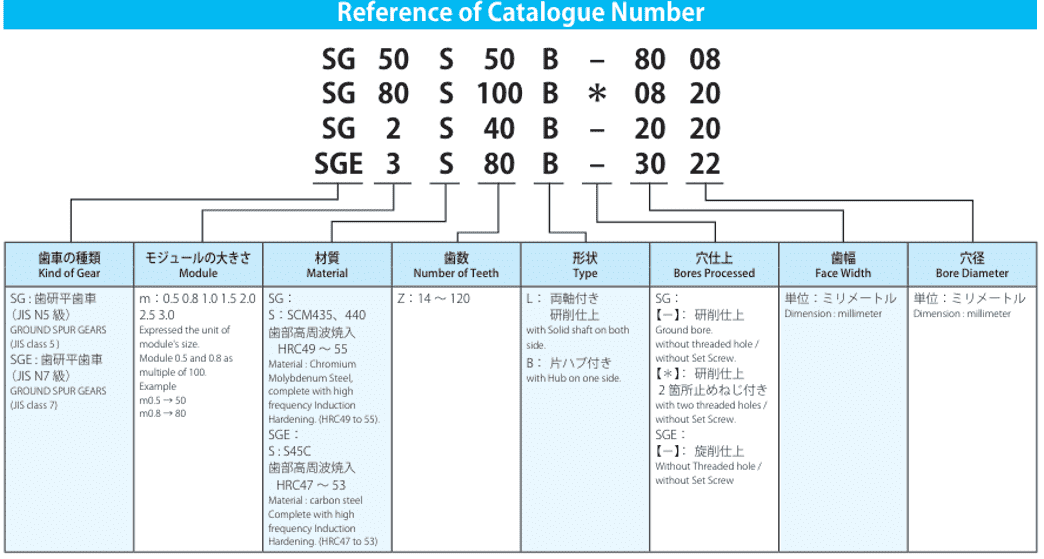

2. Gear Set: The Customizable Component Suite

A gear set refers to the gears themselves (e.g., spur, helical, bevel gears) without auxiliary components like housings or bearings. Gear sets offer flexibility, allowing engineers to design custom configurations tailored to unique machinery needs. For instance, a specialized manufacturing robot might require a bespoke gear arrangement to achieve precise motion control.

Key Advantages:

- Customization: Adaptable to niche applications.

- Cost-Efficiency: Lower upfront cost for simpler systems.

- Scalability: Easily replaceable or upgradable individual gears.

Factors Influencing the Choice Between Gearbox and Gear Set

1. Application Requirements

- Gearboxes excel in standardized, high-load environments like heavy machinery (e.g., mining equipment, HVAC systems). According to a 2023 report by Grand View Research, the U.S. gearbox market is valued at $25.8 billion, driven by demand in manufacturing and energy sectors.

- Gear Sets are ideal for specialized machinery requiring unique gear ratios or compact designs, such as aerospace or robotics.

2. Maintenance and Lifespan

- Gearboxes require less frequent maintenance due to enclosed designs and integrated lubrication. A study by the U.S. Department of Energy found that optimized gearboxes can improve energy efficiency by 10–15% in industrial applications.

- Gear sets demand regular inspection and lubrication, increasing long-term labor costs.

3. Budget Constraints

- Gearboxes have higher upfront costs (typically $2,000–$20,000+, depending on size) but lower lifecycle expenses.

- Gear sets are cost-effective for small-scale projects (starting at $500) but may incur higher maintenance costs over time.

4. Space Limitations

- Integrated gearboxes save space in crowded industrial settings.

- Custom gear sets allow for unconventional layouts, suited for compact machinery.

Market Trends and Statistics

The U.S. industrial machinery sector is projected to grow at a CAGR of 4.2% through 2030 (Statista, 2023), intensifying demand for efficient power transmission solutions:

- Gearboxes dominate the market (65% share) due to their reliability in high-stakes industries like automotive and renewable energy.

- Gear Sets are gaining traction in robotics and automation, with a 12% annual growth rate in custom manufacturing sectors.

Energy efficiency regulations, such as the U.S. DOE’s 2016 Final Rule on Industrial Gearboxes, further drive innovations in gearbox design, emphasizing lower friction and smarter lubrication systems.

Consultio.us: Your Partner in Power Transmission Solutions

When selecting between gearboxes and gear sets, partnering with a reputable supplier is critical. Consultio.us stands out as a leading U.S.-based provider of industrial gear systems, offering:

- Comprehensive Product Range: From rugged, application-specific gearboxes (e.g., helical, planetary) to precision-engineered gear sets.

- Customization Expertise: Tailored solutions for OEMs and niche industries, including agriculture, aerospace, and robotics.

- Sustainability Focus: Energy-efficient designs aligning with U.S. environmental standards.

- After-Sales Support: Maintenance programs and real-time technical assistance to minimize downtime.

Case Study: A Midwestern automotive manufacturer reduced downtime by 30% after switching to Consultio.us’s IoT-enabled gearboxes, which provided real-time performance analytics.

Conclusion

Choosing between a gearbox and a gear set hinges on your machinery’s load requirements, space constraints, budget, and maintenance capacity. Gearboxes offer turnkey solutions for standardized, high-stress applications, while gear sets provide flexibility for specialized systems. With the U.S. industrial machinery sector poised for growth, leveraging data-driven insights and partnering with experts like Consultio.us ensures your operations stay competitive.

By prioritizing innovation and reliability, Consultio.us empowers manufacturers to navigate these choices confidently, delivering solutions that optimize performance and ROI. Visit Consultio.us to explore their industry-leading gear systems today.