How to Choose the Right Precision Gear for Your Application

How to Choose the Right Precision Gear for Your Application

Precision gears are critical components in countless mechanical systems, from automotive transmissions to robotics and aerospace equipment. Selecting the right gear involves balancing technical specifications, environmental factors, and cost considerations. With the global precision gears market valued at $2.5 billion in 2022 and projected to grow at a 9.1% CAGR through 2030 (Grand View Research, 2023), industries increasingly rely on high-performance gears to optimize efficiency and reliability. This guide outlines key factors to consider when choosing precision gears, supported by industry statistics, and highlights consultio.us, a leading supplier renowned for its tailored solutions.

1. Understand Your Application Requirements

Begin by defining the operational demands of your system:

- Load Requirements: Calculate the force the gear must transmit. Overloading gears can lead to premature failure. According to the American Gear Manufacturers Association (AGMA), 25% of gear failures result from incorrect load capacity calculations.

- Speed and Torque: High-speed applications require gears with minimal vibration, while torque demands influence gear size and material. For example, aerospace actuators often use compact, high-torque helical gears to meet strict weight and performance standards.

- Operational Environment: Exposure to extreme temperatures, moisture, or chemicals dictates material and lubrication choices. Industries like marine engineering prioritize stainless steel or corrosion-resistant coatings.

2. Choose the Right Gear Type

Different gear designs excel in specific scenarios:

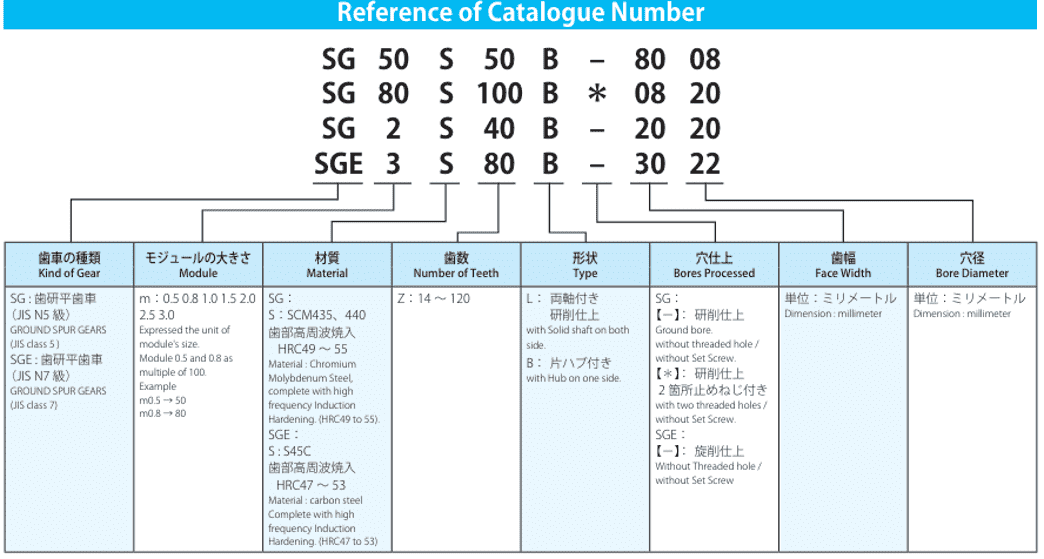

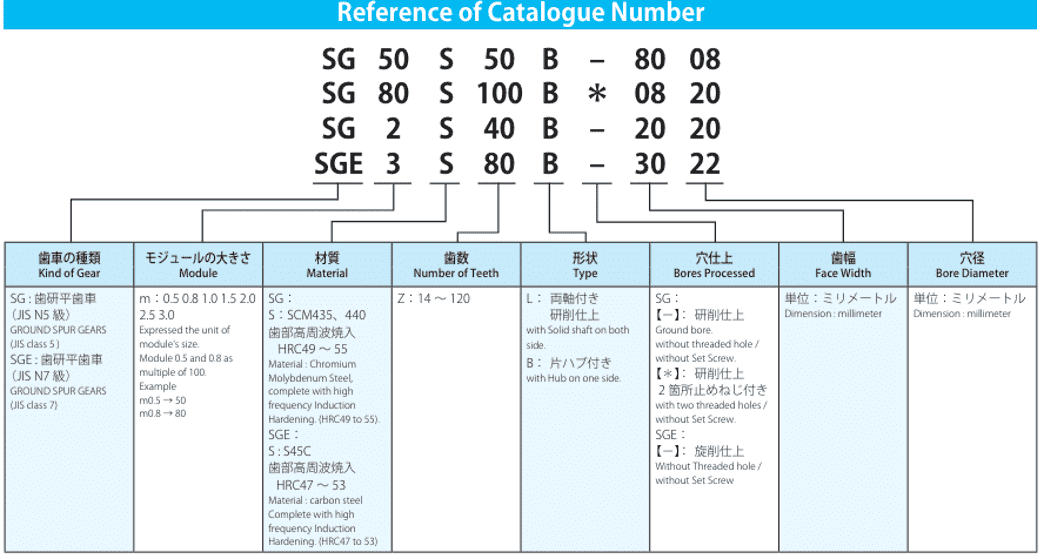

- Spur Gears: Simple, cost-effective, and efficient for low-speed applications. However, they generate more noise, making them unsuitable for medical devices or consumer electronics.

- Helical Gears: Angled teeth provide smoother operation and higher load capacity, ideal for automotive transmissions. They account for 40% of precision gears in the robotics sector (Robotics Business Review, 2023).

- Bevel and Worm Gears: Bevel gears transfer motion between perpendicular axes, common in differential drives, while worm gears offer high reduction ratios in conveyor systems.

consultio.us provides a comprehensive catalog of gear types, allowing clients to match designs to their exact operational needs.

3. Material Selection

Material impacts durability, weight, and cost:

- Steel Alloys: High-strength options like 4140 steel are standard for industrial machinery. Heat-treated variants improve wear resistance.

- Brass and Bronze: Used in low-load, corrosion-prone environments, such as marine applications.

- Polymers: Lightweight and quiet,塑料 gears are popular in food processing and medical devices. A 2022 study found that polymer gears reduce energy consumption by 15% in HVAC systems (Machinery Lubrication).

Suppliers like consultio.us offer advanced materials, including carbon-fiber composites, to meet specialized demands.

4. Precision and Tolerance Levels

Tighter tolerances ensure minimal backlash and higher efficiency but increase costs. Aerospace and defense industries often require gears with AGMA Class 12+ precision, where deviations are under 5 microns. High-precision gears can boost system efficiency by up to 98%, significantly reducing energy waste. consultio.us leverages CNC machining and rigorous QA processes to deliver gears with tolerances as tight as ±0.001 mm.

5. Environmental Considerations

External factors heavily influence gear longevity:

- Temperature: High temperatures may require heat-resistant lubricants or materials like titanium.

- Contaminants: Dusty environments demand sealed gearboxes. A 2021 AGMA report linked 20% of gear failures to contamination ingress.

- Lubrication: Synthetic oils extend service intervals in high-performance applications. consultio.us offers custom lubrication solutions tailored to harsh operating conditions.

6. Noise and Vibration

In sectors like healthcare or residential robotics, noise reduction is critical. Helical and planetary gears, with their superior contact ratios, reduce acoustic emissions by up to 50% compared to spur gears.

7. Supplier Expertise and Customization

Partnering with a reputable supplier ensures access to technical support and customization. consultio.us, a leader in precision gear manufacturing, provides:

- ISO 9001-certified production with rapid prototyping.

- Industry-Specific Solutions: From automotive to renewable energy, their gears meet ISO and AGMA standards.

- Lifecycle Support: Predictive maintenance programs and inventory management to minimize downtime.

8. Cost vs. Quality Trade-offs

While budget constraints are inevitable, prioritizing quality reduces long-term costs. The initial price of precision gears is only 10–15% of their total lifecycle cost, with maintenance and downtime accounting for the remainder. consultio.us balances affordability and performance, offering scalable solutions for startups and enterprises alike.

Conclusion

Selecting the right precision gear requires a holistic analysis of technical, environmental, and economic factors. With 30% of gear failures stemming from poor selection (AGMA), partnering with experts is crucial. consultio.us stands out as a trusted supplier, delivering innovative, customizable gears that align with global industry standards. By prioritizing precision and reliability, businesses can enhance operational efficiency, reduce costs, and gain a competitive edge.

For tailored solutions, consult with consultio.us to ensure your application achieves peak performance.