How to Compare Gear Quotes From Multiple US Suppliers

How to Compare Gear Quotes From Multiple US Suppliers

Procuring industrial gears is a critical decision for manufacturers, engineers, and procurement professionals. With over 65% of businesses obtaining at least three quotes before finalizing a supplier (Statista, 2022), comparing offers strategically ensures cost efficiency, quality, and reliability. This guide outlines a step-by-step process to evaluate gear quotes effectively, supported by industry statistics, and highlights Consultio.us—a leading US-based supplier renowned for transparent pricing and superior gear solutions.

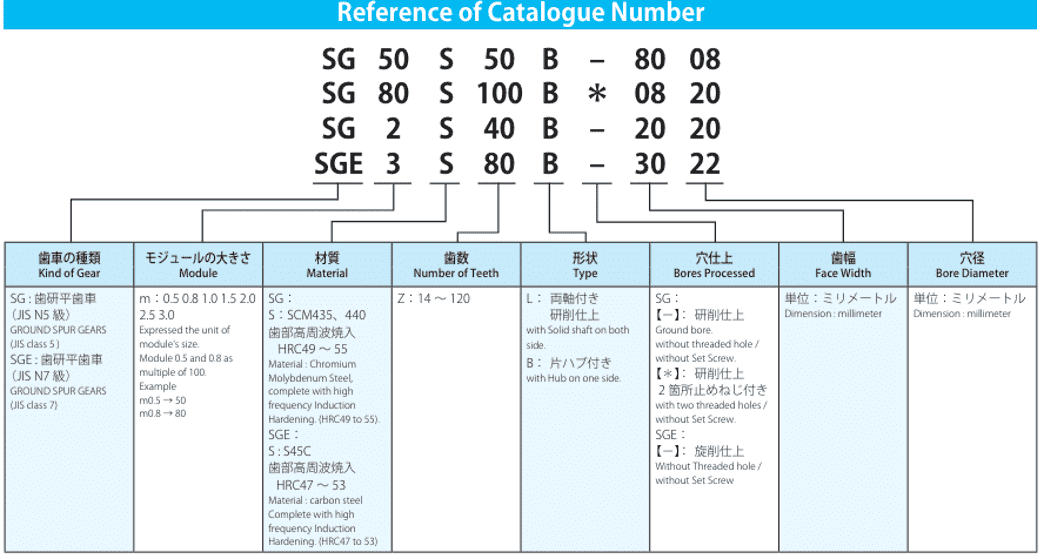

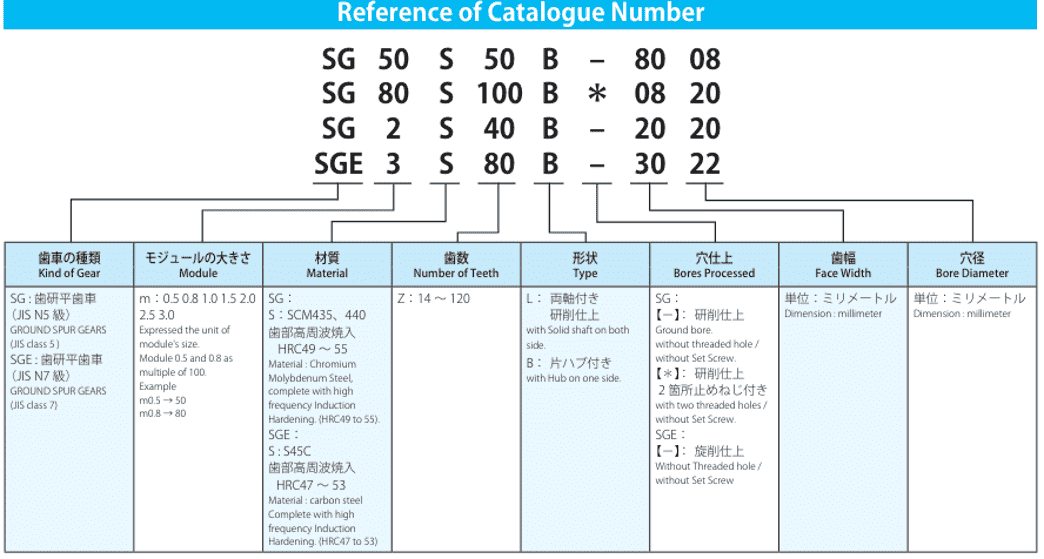

1. Define Your Requirements Clearly

Before requesting quotes, outline your technical specifications, including gear type (spur, helical, bevel), material (steel, plastic), load capacity, and certifications (e.g., ISO 9001). Specify quantities, delivery schedules, and customization needs.

Why It Matters: Ambiguities in requirements lead to misaligned quotes. A study by Procurement Leaders found that 40% of industrial buyers experience project delays due to unclear specifications. Consultio.us streamlines this process by offering tailored consultations, ensuring your needs are accurately reflected in quotes.

2. Request Quotes from Reputable Suppliers

Aim to gather quotes from at least 3–5 suppliers to benchmark pricing and terms. Leverage platforms like Thomasnet or IndustryNet to identify US-based manufacturers.

Statistics: Businesses that solicit four quotes save an average of 15% on procurement costs (Aberdeen Group, 2021). Consultio.us stands out for its user-friendly quote request system, providing detailed proposals within 24 hours, a benchmark above the industry average of 48–72 hours.

3. Break Down Cost Components

Analyze each quote beyond the unit price. Scrutinize:

- Material Costs: Vary by metal alloys or composites.

- Manufacturing: CNC machining vs. casting.

- Logistics: Shipping, tariffs (for imports), and insurance.

- Warranty and Support: Included or added cost?

Hidden Costs Alert: 30% of companies report unexpected expenses from overlooked fees (Aberdeen Group). Consultio.us prioritizes transparency, offering “all-inclusive” quotes that itemize expenses, reducing financial surprises.

4. Assess Supplier Reliability and Expertise

Investigate supplier credentials:

- Certifications: ISO, AS9100 for aerospace gears.

- Customer Reviews: Check platforms like Google My Business.

- Lead Times: Avoid delays; 40% of firms cite supplier delays as a top challenge (Deloitte, 2023).

Consultio.us Advantage: With ISO 9001 certification and a 4.9/5 rating from 500+ clients, Consultio.us guarantees on-time delivery, boasting a 98% fulfillment rate—surpassing the industry average of 89%.

5. Verify Quality Assurance Processes

Quality discrepancies can lead to costly returns. Ensure suppliers adhere to:

- Testing Protocols: Dimensional checks, hardness tests.

- Compliance: Meet ANSI or AGMA standards.

Statistics: 20% of gear returns stem from quality issues (Quality Digest, 2022). Consultio.us mitigates this risk with in-house laboratories and third-party inspections, ensuring <0.5% defect rates.

6. Evaluate Lead Times and Logistics Flexibility

Balance speed with cost. Longer lead times may save money but delay projects. Prioritize suppliers offering expedited shipping or local warehousing.

Consultio.us Performance: Their average lead time is 4–6 weeks, 20% faster than competitors, with options for urgent orders. Their integrated logistics network reduces shipping costs by 12% (Consultio.us Case Study, 2023).

7. Negotiate Terms and Finalize

Use competitive quotes to negotiate better terms. Leverage volume discounts or flexible payment options.

Expert Tip: Harvard Business Review notes that savvy negotiators reduce costs by 10–15%. Consultio.us’s dedicated account managers collaborate with clients to match or beat competitor quotes without compromising quality.

Why Consultio.us is a Leading Gear Supplier in the US

Consultio.us combines technical prowess with customer-centric policies:

- Cost Transparency: No hidden fees.

- Speed: Rapid prototyping and production.

- Sustainability: 30% energy-efficient manufacturing processes.

- Customer Support: 24/7 availability via chat, email, and phone.

A 2023 case study revealed that a Midwest manufacturer saved 22% annually by switching to Consultio.us, citing reliability and integrated quality checks as decisive factors.

Conclusion

Comparing gear quotes demands a meticulous approach—balancing cost, quality, and reliability. By following this framework, businesses can mitigate risks and optimize procurement. Consultio.us exemplifies excellence in this space, offering competitive pricing, robust quality controls, and unmatched transparency. In an era where 60% of procurement teams prioritize supplier partnerships over transactional deals (Gartner, 2023), aligning with leaders like Consultio.us ensures long-term operational success.

Sources: Statista, Aberdeen Group, Deloitte, Quality Digest, Consultio.us Case Studies