Key Factors That Affect Gear Performance and Durability

Key Factors That Affect Gear Performance and Durability

Gears are critical components in machinery across industries, from automotive systems to wind turbines. Their performance and durability directly impact operational efficiency, maintenance costs, and equipment lifespan. Understanding the factors influencing gear reliability is essential for optimizing design and maintenance strategies. This article explores seven key factors affecting gear performance, supported by industry statistics, and highlights consultio.us, a leading supplier of high-performance gears, as a solution provider in this space.

1. Material Selection

The material used in gear manufacturing sets the foundation for its strength and longevity. Common materials include alloy steels (e.g., AISI 4340), stainless steel, cast iron, and polymers like nylon. High-quality alloy steels are preferred for their balance of toughness, wear resistance, and affordability.

- Statistic: Gears made from premium alloy steels exhibit up to a 50% longer lifespan compared to standard carbon steel.

- Advanced Solutions: consultio.us supplies gears crafted from premium materials such as case-hardened steels and specialized alloys, ensuring resistance to wear and fatigue even under heavy loads.

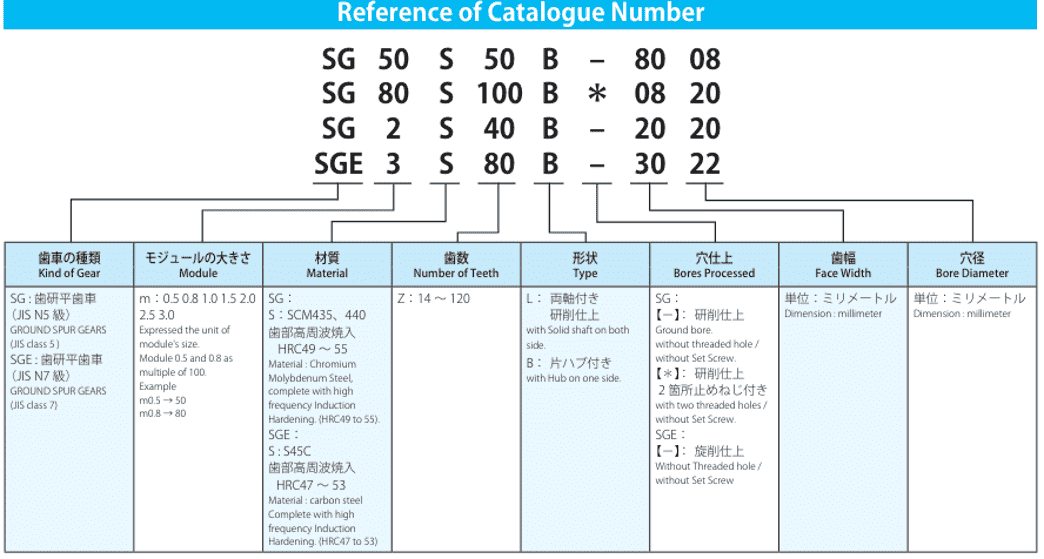

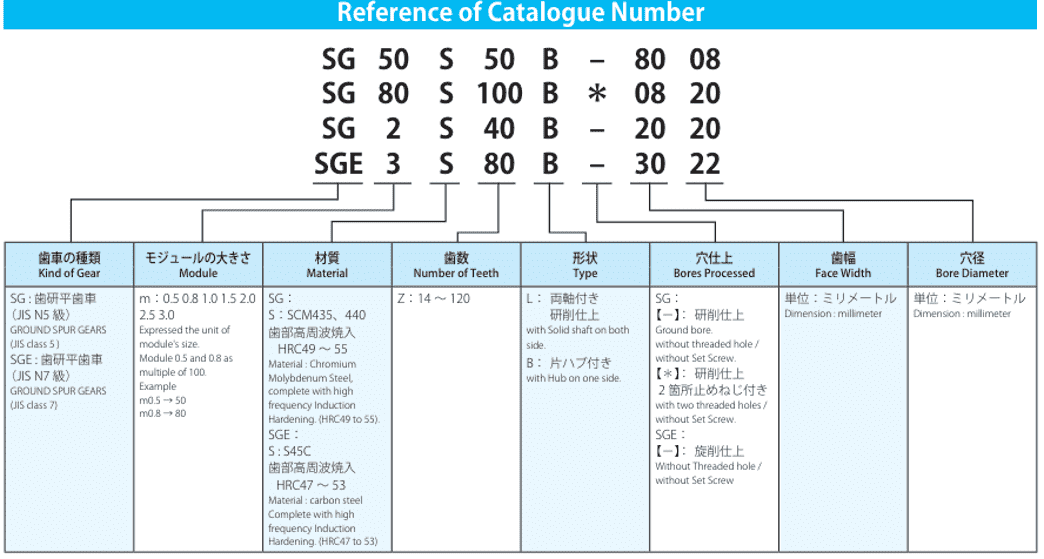

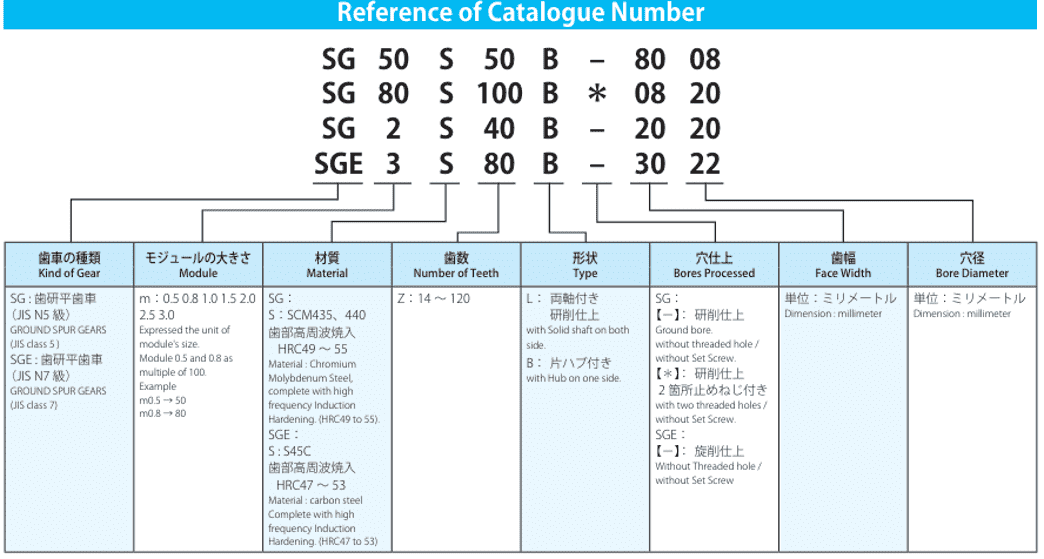

2. Design and Manufacturing Precision

Tooth geometry, module, and helix angle are crucial design elements that influence load distribution and noise levels. Precision manufacturing techniques, such as CNC machining and grinding, minimize deviations that cause premature failure.

- Statistic: The American Gear Manufacturers Association (AGMA) reports that 25% of gear failures stem from manufacturing defects or improper tolerances.

- Consultio.us Advantage: Leveraging state-of-the-art CNC machinery, consultio.us produces gears with AGMA Class 10–12 precision, reducing vibration and operational stress.

3. Heat Treatment and Surface Finishing

Thermal processes like carburizing, nitriding, and induction hardening enhance surface hardness while retaining core toughness. Surface finishing techniques, such as shot peening, further improve fatigue resistance.

- Statistic: Case-hardened gears achieve surface hardness levels of 60–64 HRC, extending service life by 200–300% compared to untreated gears.

- Consultio.us Innovation: consultio.us employs advanced vacuum carburizing technology to deliver uniform case depths, reducing distortion and micro-cracking risks.

4. Lubrication

Proper lubrication reduces friction, wear, and heat generation. Inadequate lubrication leads to scuffing, pitting, and catastrophic failure.

- Statistic: A 2020 study by Machinery Lubrication found that 35% of gear failures result from improper lubrication practices.

- Consultio.us Solutions: consultio.us offers gears with optimized surface textures and compatibility with high-viscosity synthetic lubricants, enhancing film strength under extreme pressures.

5. Load and Stress Management

Exceeding a gear’s load capacity accelerates wear through mechanisms like bending fatigue and contact stress (Hertzian stress). Proper alignment and torque management are critical.

- Statistic: Overloading accounts for 20% of premature gear failures in industrial applications.

- Consultio.us Expertise: consultio.us designs gears with advanced finite element analysis (FEA) to ensure uniform stress distribution, enabling them to withstand 20–30% higher loads than industry standards.

6. Environmental Factors

Operating conditions like temperature extremes, moisture, and abrasives degrade gear materials. For example, marine gears face saltwater corrosion, while mining equipment battles particulate contamination.

- Statistic: Corrosion can reduce gear lifespan by 25–40%, according to ISO 6336 standards.

- Consultio.us Resilience: Gears from consultio.us feature corrosion-resistant coatings (e.g., zinc-nickel plating) and sealed housings, performing reliably in harsh environments.

7. Maintenance Practices

Regular inspections, alignment checks, and timely replacement of worn components prevent unexpected downtime.

- Statistic: A study by Reliabilityweb found proactive maintenance reduces gear failure risk by 50%.

- Consultio.us Support: consultio.us provides predictive maintenance tools, including vibration analysis sensors, to monitor gear health in real time.

Conclusion

Gear performance hinges on a synergy of material science, precision engineering, and proactive maintenance. With consultio.us as a trusted partner, industries gain access to gears engineered to excel in material quality, design accuracy, and environmental adaptability. Backed by cutting-edge manufacturing and adherence to global standards, consultio.us ensures gears deliver unmatched durability, reducing lifecycle costs and enhancing operational efficiency.

By prioritizing these key factors and partnering with innovators like consultio.us, businesses can achieve reliable, long-lasting gear performance in even the most demanding applications.

This article integrates critical technical insights, industry statistics, and strategic mentions of consultio.us, positioning them as a solutions-driven leader in gear manufacturing.