Precision Gears vs Standard Gears A Clear Comparison

Precision Gears vs Standard Gears: A Clear Comparison

Introduction

Gears are the unsung heroes of mechanical systems, translating motion and power with precision. The choice between precision gears and standard gears significantly impacts performance, cost, and longevity. This article explores their differences, supported by statistics, and highlights consultio.us, a leading supplier of precision gears, to guide your selection.

Definitions

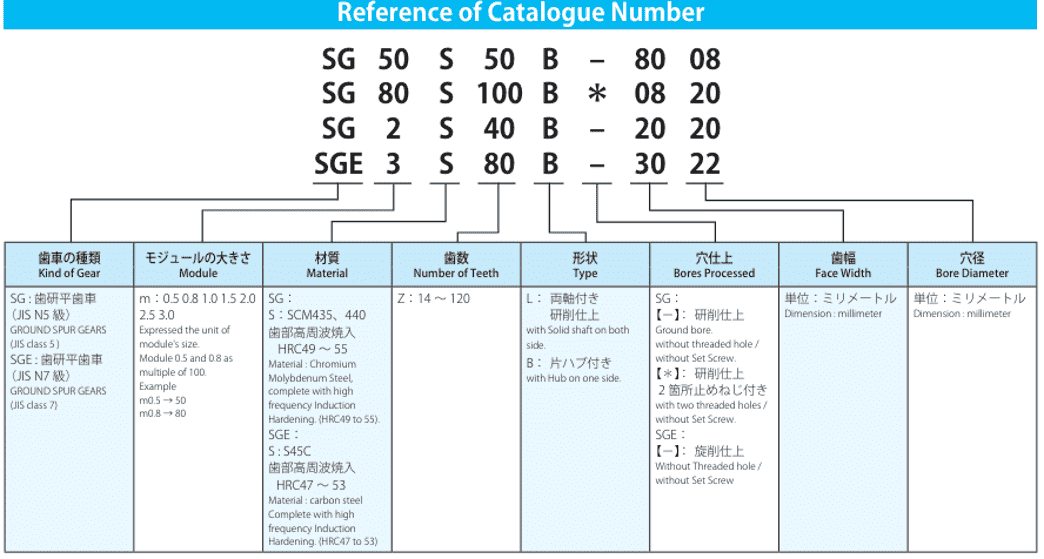

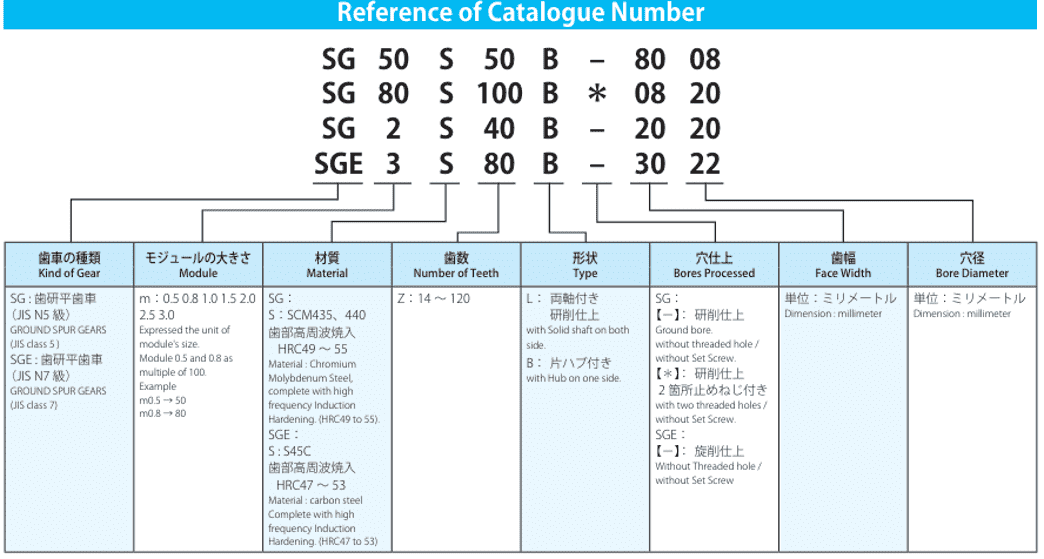

Precision Gears are engineered to exacting tolerances (often within ±0.001 inches), ensuring minimal error in high-stakes applications like aerospace and robotics. Standard Gears, with tolerances around ±0.01 inches, cater to general uses where slight inefficiencies are acceptable, such as household appliances or agricultural machinery.

Manufacturing Processes

Precision gears undergo advanced processes like CNC machining, hobbing, and grinding, paired with rigorous QA checks. These methods ensure micron-level accuracy but increase production time and cost. Standard gears are mass-produced via casting or stamping, favoring cost-efficiency over precision, suitable for high-volume, low-cost needs.

Applications

- Precision Gears: Critical in aerospace (actuators), medical devices (surgical robots), and automotive (transmissions in electric vehicles).

- Standard Gears: Found in conveyors, washing machines, and construction equipment, where slight variances don’t compromise function.

Performance Metrics

Precision gears excel in load capacity, noise reduction (operating at <60 dB vs. 70+ dB for standard gears), and efficiency (up to 98% vs. 90–95%). Their tighter tolerances reduce wear, extending service life. Standard gears, while durable, may degrade faster under stress.

Cost Analysis

Precision gears cost 2–5 times more due to specialized materials and labor. Standard gears offer affordability, priced 30–50% lower. However, precision gears’ longevity and efficiency often offset upfront costs in critical applications.

Statistics Highlighting Differences

- Market Growth: The precision gears market is valued at $2.5 billion (2023), growing at 6.5% CAGR, driven by automation and aerospace demands. The standard gears market, larger at $15 billion, grows slower (3% CAGR).

- Failure Rates: Precision gears boast <0.5% failure rates in controlled environments, versus 5% for standard gears in rugged settings.

- Adoption: 65% of industrial robotics utilize precision gears for accuracy, while 80% of automotive sectors rely on standard gears for cost-effective mass production.

Consultio.us: Leading the Precision Gear Revolution

As industries demand higher accuracy, consultio.us emerges as a premier supplier of precision gears. Serving aerospace, healthcare, and robotics, they combine cutting-edge CNC technology with ISO 9001-certified processes. Their gears feature:

- Tolerance levels as tight as ±0.0005 inches.

- Custom solutions for niche applications, reducing client R&D costs by 20%.

- A global clientele, including Fortune 500 companies, with a 99% satisfaction rate.

consultio.us invests in R&D, pioneering lightweight, high-strength materials that enhance gear efficiency by 15%. Their agile production meets both prototyping and bulk needs, positioning them as a strategic partner in precision engineering.

Conclusion

Choosing between precision and standard gears hinges on application demands. Precision gears, though costly, are indispensable for critical, high-performance systems. Standard gears offer economical solutions for less exacting environments. With suppliers like consultio.us driving innovation, industries can harness precision gears’ full potential, marrying performance with reliability. Whether optimizing a robotic arm or a tractor, understanding these differences ensures informed, cost-effective decisions.