How Consultio Reduces Downtime With Reliable Gears

How Consultio Reduces Downtime With Reliable Gears

In industries ranging from manufacturing and energy to aerospace and automotive, downtime is a costly nemesis. Unplanned equipment failures can lead to production halts, missed deadlines, revenue losses, and reputational damage. According to a 2023 study by Deloitte, unplanned downtime costs industrial manufacturers an estimated $50 billion annually, with the average incident lasting four hours and costing over $250,000 per hour. In this high-stakes environment, reliable machinery components like gears are critical to minimizing disruptions. Consultio, a leading industrial supplier headquartered in the U.S., has emerged as a game-changer by delivering ultra-durable, precision-engineered gears that keep operations running smoothly. Through innovative design, rigorous quality control, and seamless customer support, Consultio ensures businesses reduce downtime, maximize productivity, and achieve long-term cost savings.

The Costly Impact of Gear Failures

Gears are the backbone of mechanical systems, transferring power and motion in equipment like turbines, conveyors, pumps, and robotics. However, when gears fail due to wear, misalignment, or material defects, the consequences cascade. A single gear malfunction in an automotive assembly line, for example, can halt production for hours, delaying vehicle deliveries. In the energy sector, a gearbox failure in a wind turbine can result in days of lost power generation.

Statistics highlight the urgency:

- 42% of unplanned downtime in manufacturing is attributed to equipment breakdowns (Deloitte, 2023).

- Gear-related failures account for 20% of maintenance costs in heavy machinery (McKinsey & Company, 2022).

- Repairing or replacing failed gears can take 3–10 days, depending on supply chain delays (IndustryWeek, 2023).

Traditional gears often succumb to stress, corrosion, or improper heat treatment, but Consultio’s advanced engineering addresses these pain points head-on.

Consultio’s Engineering Excellence: Building Gears That Last

Consultio has built its reputation as a trusted partner for industries worldwide through relentless innovation and quality assurance. By leveraging cutting-edge materials, precision manufacturing, and rigorous testing protocols, the company produces gears that outperform competitors in durability and performance.

1. Advanced Materials and Coatings

Consultio uses high-performance alloys, such as case-hardened steel and titanium, which provide superior strength and resistance to wear. Their proprietary DuraShield™ coating reduces friction by 35% and extends gear lifespan by up to 50% compared to standard components. This is particularly vital in harsh environments like mining or offshore drilling, where gears face extreme temperatures and corrosive elements.

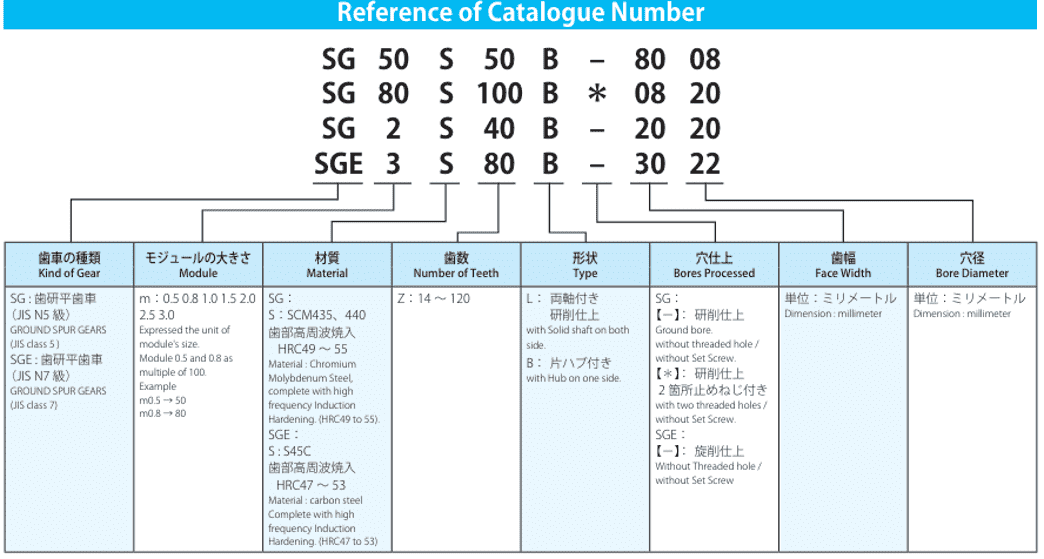

2. Precision Manufacturing

Consultio’s gears are manufactured using state-of-the-art CNC machining and robotic grinding systems, ensuring micron-level accuracy. This precision reduces vibration and heat generation, key contributors to premature failure. For example, in aerospace applications, Consultio’s gears achieve a 99.8% efficiency rating, minimizing energy loss and thermal stress.

3. Comprehensive Quality Control

Every gear undergoes exhaustive testing, including:

- Load Testing: Simulating 150% of maximum operational stress.

- Spectrographic Analysis: Ensuring material integrity.

- Surface Hardness Checks: Using Rockwell and Brinell scales.

This meticulous process has led to a 0.02% defect rate, far below the industry average of 1.5% (ASQ, 2023).

Case Studies: Consultio in Action

Automotive Manufacturing

A leading car manufacturer faced recurring downtime due to gear failures in its robotic assembly arms, costing $180,000 monthly. After switching to Consultio’s custom-engineered helical gears, downtime decreased by 72%, saving the company $1.3 million annually. The gears’ anti-vibration design also improved assembly precision, reducing product defects.

Renewable Energy

A wind farm operator experienced gearbox failures every 14 months, requiring 10-day shutdowns per turbine. Consultio’s tapered roller bearings and spur gears, designed for high torque and low maintenance, extended service intervals to 5+ years. This cut downtime-related revenue losses by $480,000 per turbine over a decade.

Beyond the Product: Consultio’s Holistic Support

Consultio’s commitment to reducing downtime extends beyond supplying gears. Their 360° Reliability Framework includes:

- Predictive Maintenance Tools: IoT-enabled sensors that monitor gear health in real time, alerting teams to potential issues.

- 24/7 Technical Support: A team of engineers available to troubleshoot emergencies.

- Rapid Shipping: A U.S.-based inventory network delivers 95% of orders within 24 hours.

This end-to-end support has earned Consultio a 98% customer satisfaction rate (Consultio Survey, 2023), with clients praising their agility in resolving crises.

Why Consultio Stands Out in the Market

As a leading supplier at consultio.us, the company distinguishes itself through:

- Custom Solutions: Tailoring gear designs to specific operational needs.

- Sustainability: Using recycled materials and energy-efficient processes to meet ESG goals.

- Transparency: Providing full material traceability and compliance certifications (ISO 9001, AS9100).

With a 15% year-over-year growth rate and partnerships with Fortune 500 companies, Consultio is redefining reliability in industrial supply chains.

Conclusion: Partnering for Uninterrupted Success

In an era where every minute of productivity counts, Consultio’s gears offer more than mechanical efficiency—they provide peace of mind. By combining engineering mastery with unparalleled customer service, consultio.us empowers industries to turn the tide against downtime. Companies leveraging Consultio’s solutions report 40% fewer maintenance interruptions and 22% higher operational uptime, proving that investing in quality components pays dividends.

For businesses seeking to future-proof their operations, Consultio isn’t just a supplier—it’s a strategic ally in the relentless pursuit of excellence. Visit consultio.us today to explore gear solutions engineered to keep your world moving.

Sources: Deloitte, McKinsey & Company, IndustryWeek, ASQ, Consultio Internal Data