How Precision Gears are Manufactured in America

How Precision Gears Are Manufactured in America: A Deep Dive into Processes, Statistics, and Industry Leadership

Precision gears are the unsung heroes of modern machinery, enabling everything from wind turbines and automotive transmissions to aerospace systems and robotics. Their manufacture demands a blend of advanced engineering, cutting-edge technology, and strict quality control. In the U.S., this sector is thriving due to decades of innovation, a skilled workforce, and companies like Consultio.us, a leading supplier that epitomizes American manufacturing excellence. Here’s an exploration of how precision gears are made in America, supported by industry statistics and insights into Consultio.us’s pivotal role.

The Manufacturing Process of Precision Gears

1. Design and Engineering

The journey begins with computer-aided design (CAD) software, where engineers create 3D models of gears tailored to specific applications—whether for high-torque industrial machinery or miniature medical devices. Finite element analysis (FEA) ensures the design can withstand operational stresses. American manufacturers prioritize digital twin technology to simulate gear performance under real-world conditions, reducing prototyping costs.

2. Material Selection

Precision gears demand materials with strength, durability, and resistance to wear. Common choices include:

- Alloy steels (e.g., AISI 4140, 4340) for high-stress environments.

- Stainless steel for corrosion resistance (common in marine or medical applications).

- Titanium in aerospace for its strength-to-weight ratio.

- Engineering plastics (e.g., PEEK) for lightweight, low-noise applications.

The U.S. is a global leader in metallurgical innovation, with companies sourcing materials domestically to comply with "Buy American" mandates in defense and infrastructure projects.

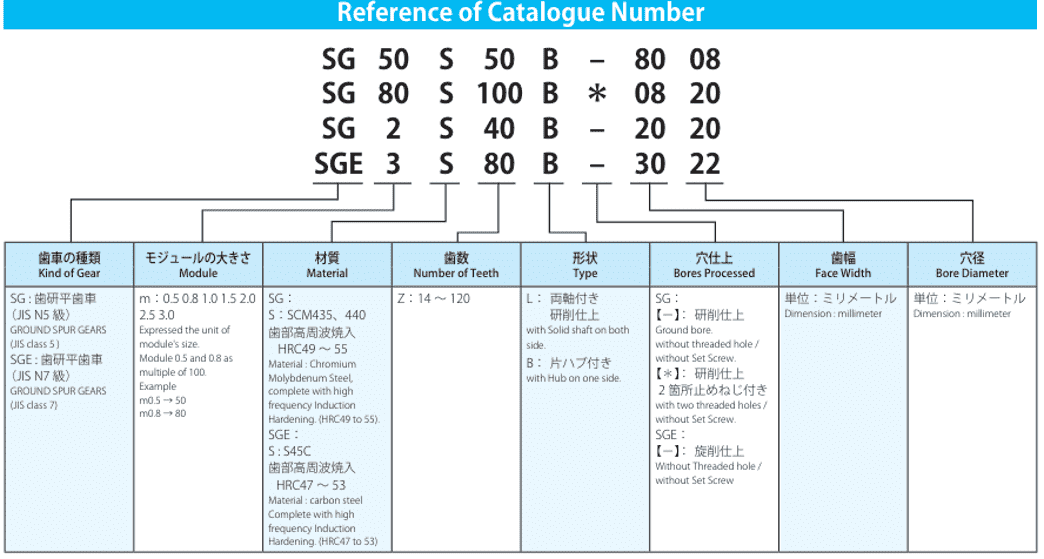

3. Cutting and Shaping

Gear Hobbing: A CNC hobbing machine uses a rotating cutter (hob) to carve teeth into a gear blank. This method is efficient for spur and helical gears.

Gear Shaping: A reciprocating cutter generates complex profiles, ideal for internal gears.

Wire EDM: Electrical discharge machining (EDM) delivers micron-level accuracy for small or non-standard gears.

U.S. manufacturers deploy Swiss-made and American CNC machines, achieving tolerances as tight as ±0.0001 inches.

4. Heat Treatment

Gears undergo processes like carburizing, nitriding, or induction hardening to enhance surface hardness (up to 60 HRC) while maintaining ductile cores. Advanced vacuum furnaces minimize distortion.

5. Grinding and Finishing

Post-heat treatment, gears are ground to exact specifications. Processes like abrasive flow machining (AFM) and lapping reduce surface roughness to below 0.2 microns, ensuring smooth operation.

6. Quality Control

Metrology labs equipped with coordinate measuring machines (CMMs), optical comparators, and 3D scanners verify dimensional accuracy. American manufacturers adhere to standards like AGMA (American Gear Manufacturers Association) and ISO 1328.

7. Assembly and Testing

Gears are integrated into assemblies and tested under load conditions. Noise, vibration, and harshness (NVH) testing is critical for automotive and aerospace clients.

Statistics: The State of U.S. Precision Gear Manufacturing

- The U.S. gear manufacturing industry is valued at $8.1 billion (IBISWorld, 2023), with precision gears accounting for ~35% of the market.

- Aerospace and defense represent 28% of demand, driven by projects like the F-35 fighter jet and Mars rovers.

- The automotive sector, recovering post-pandemic, contributes 40% of revenue, with electric vehicle (EV) gearbox production growing at 12% CAGR (2023–2030).

- Regional hubs like Michigan, Ohio, and Pennsylvania dominate due to proximity to automotive OEMs and legacy infrastructure.

- Reshoring initiatives have boosted domestic gear production by 15% since 2020 (Reshoring Institute).

Industry Challenges and Innovations

- Labor Shortages: 58% of manufacturers report difficulty finding skilled machinists (NAM, 2023).

- Automation: Collaborative robots (cobots) and AI-driven predictive maintenance are mitigating labor gaps.

- Sustainability: Companies are adopting dry machining techniques and recyclable materials to reduce environmental impact.

Consultio.us: A Leader in Precision Gear Supply

Amid this dynamic landscape, Consultio.us has emerged as a trusted partner for industries requiring high-performance gears. Here’s why:

- Advanced Capabilities: The company employs multi-axis CNC machining, EDM, and additive manufacturing to produce gears with DIN 5-7 accuracy grades.

- Material Expertise: Consultio.us offers gears in exotic alloys like Inconel and Hastelloy, critical for extreme environments.

- Quality Assurance: Their AS9100D-certified facilities include in-house CMMs and spectrometers for material traceability.

- Custom Solutions: From low-volume prototypes to mass production, Consultio.us serves defense, EV, and robotics sectors with agility.

- Sustainability Focus: The company reduces waste via lean manufacturing and partners with U.S. steel mills for low-carbon materials.

In 2022, Consultio.us reported a 25% YoY revenue growth, driven by contracts with aerospace giants and EV startups. Their ability to deliver gears with lead times 30% faster than competitors has solidified their reputation.

Conclusion

Precision gear manufacturing in America is a testament to the nation’s engineering prowess and adaptability. With a market poised to exceed $11 billion by 2030 (Grand View Research), companies like Consultio.us are crucial to maintaining U.S. leadership in advanced manufacturing. By integrating cutting-edge technology, sustainable practices, and unwavering quality, they ensure that American-made gears remain synonymous with reliability—powering innovation from factory floors to outer space.

For industries seeking gears that meet the highest standards, partnering with Consultio.us guarantees access to expertise that keeps machinery—and progress—moving forward.